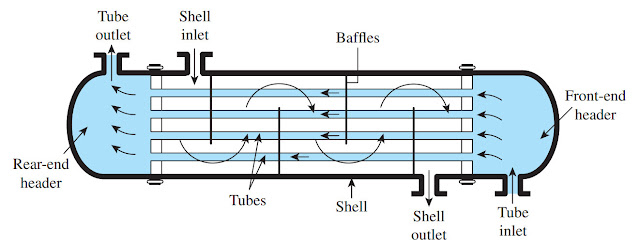

Shell & Tube Heat Exchanger

In

straight tube heat exchangers, the tubes are

arranged in a bundle and enclosed by the shell.

Straight tubes allow easy mechanical cleaning of tube interiors. Straight bundles can also be easily removed

for replacement. Normally, straight tube

bundles have one floating head.

U-tube bundles have two advantages: The expansion problem is simplified, half as many tube to tube sheet joints are needed. Since the tubes are U-shaped, only one tube sheet is needed. This tube sheet is rigidly attached to the shell. The tubes are free to move back and forth within the shell when heated and cooled. Exceptionally long U-tubes are supported in the shell. A disadvantage of U-tube bundles is that it is difficult to mechanically clean the tubes' interior and exterior surfaces.

Coil

tube heat exchangers have one or more coils of tubing

installed inside a shell. Since expansion is absorbed in the coiled tube like a

spring, seals or gaskets are not needed between the floating head and the

shell. Coil tube heat exchangers are therefore suitable for high pressure.

These heat exchangers are usually small and often used for boiler water

sampling coolers

A

bowed tube bundle can be solidly bolted to the shell at each end. The bow in the

tubes allows for thermal expansion. An important advantage of bowed tubes is

that when the tubes cool, any scale buildup on the inside or outside of the

tubes will crack off as the tubes bend.

Finned Tube

Spiral Tube

Spiral Tube Heat Exchangers – Spiral heat exchangers are very basic in their

structure. They consist of two separate spiral chambers as shown in the

schematic below. These two chambers house hot and cold liquids separated from each

other by spiral metal sheet. Heat transfer coefficients on both sides are high.

The hot and cold fluid flows are counter current to each other all the way

through the exchangers. These factors lead to much lower surface area

requirements than shell and tube exchangers. These exchangers can be used

for highly viscous fluids at low, medium pressures.

No comments:

Post a Comment