HEAT TRANSFER

LATENT HEAT

SPECIFIC HEAT

SENSIBLE HEAT

Centigrade - ° C

Fahrenheit - ° F

Kelvin - ° K

HEAT EXCHANGER ≠ HEAT CHANGER

PRINCIPLE

A heat exchanger is a device that transfers heat energy from one fluid to another.

Many different types of heat exchangers are used in the power plant.

Terminologies used depends on applications are, Condenser, Heater, Cooler, Chiller, Steam Generator, Evaporator, Vaporiser etc.

Classification:

Fluid contact: Direct contact heat exchanger

Surface contact heat exchanger

Direct Contact Heat Exchanger:

Direct contact heat exchangers transfer heat from one fluid to another by direct contact of the fluids.

Two types of direct contact heat exchangers are:

Evaporative

Complete mixing heat exchangers

Example:

Cooling Towers

Distillation (Fractional) Column

Surface Contact Heat Exchanger:

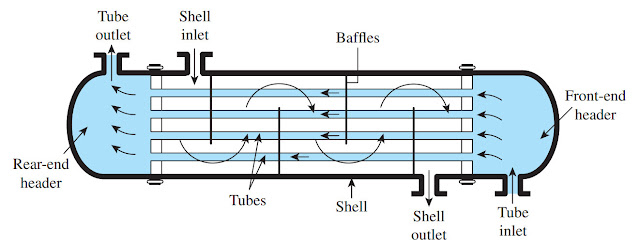

Surface heat exchangers transfer heat from one fluid through a surface to another fluid at a lower temperature. Most surface heat exchangers used in power plants are the shell and tube type. For example, Feed water heaters, Condensers, and Lube oil coolers are shell and tube surface heat exchangers.

Tubular type:

Shell & Tube

Tube arrangement: Straight tube, U tube, Bowed tube, Coiled tube

Position: Vertical, Horizontal

No of Pass (Flow arrangement): single pass, Multiple pass

Single pass: Here the fluid flows once

through the heat exchanger along its length.

Multi pass: Here the fluid flows through the heat exchanger along its length and then it’s reversed again through the whole length. In multi pass arrangements the flow can pass along the length of heat exchanger in multiple times. Heat transfer is more as the number of passes are increases.

Flow Direction: Counter flow, Parallel flow, Cross flow

Counter flow heat exchanger, in which the two fluids

flow parallel but in opposite directions. This type of flow

arrangement allows the largest change in temperature of both fluids and is

therefore most efficient.

Parallel flow heat exchangers, in which the two fluids flow parallel to each other in same direction. This is less efficient than counter flow but does provide more uniform wall temperatures.

Cross flow heat exchangers, in which the two fluids flow at right angles to each other. The efficiency is intermediate between counter flow and parallel flow heat exchangers.

Plate type: